Glimpse into the world of lactose

Authors: Geetanjali Laghate, Radhika Thakkar and Dr. Heeshma Shah

Company: Signet Chemical Corporation Pvt. Ltd. – Technical Services Department

Introduction:

A robust formulation is one that should be able to accommodate typical variability in API, excipients, and processes. The choice of excipients is hence of utmost importance. An excipient is chosen based on its functionality as well as chemical compatibility with the drug substance. In the pharmaceutical industry, lactose is one of the oldest and still widely used filler and diluent in tablets and capsules. The reason for its popularity is attributed to its properties like low hygroscopicity, water solubility, compatibility with active ingredients and other excipients, excellent physical and chemical stability. Depending on the manufacturing process, different types of lactose are formed having application in varied processes like wet granulation, direct compression, roller compaction, fluid bed processing, etc. Apart from oral delivery, it also finds application in parenteral formulations and dry powder inhalers. The additional advantage of lactose over other range of excipients is its availability and cost effectiveness.

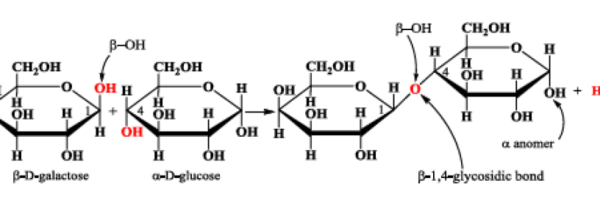

Lactose is a naturally occurring disaccharide derived from the condensation of β-D-galactose and α-D-glucose, which form a β-1,4-glycosidic linkage as seen in Figure 1.

Lactose exists in two isomeric forms viz. α and β lactose respectively. The difference in these two forms is due to the position of the hydrogen atom and hydroxyl group on carbon atom no. 1 of the glucose moiety. Interestingly, alpha and beta-lactose morph back and forth into one another due to a phenomenon called mutarotation. The rate of mutarotation is influenced by a number of conditions including the concentration of lactose, the temperature and the acidity, or pH, of the milk. At room temperature, the ratio of isomers is about 40% alpha to 60% beta lactose.

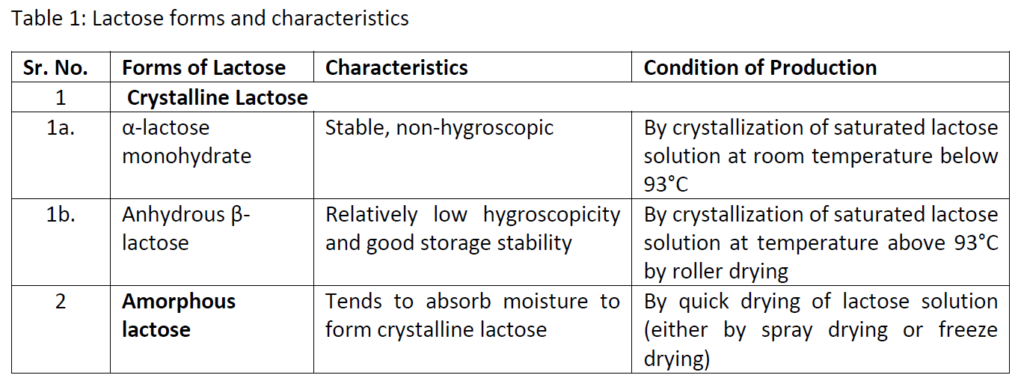

Lactose is available in two states i.e. crystalline and amorphous. Crystalline lactose is widely used in pharmaceutical industry and can majorly exist in the form of α-lactose monohydrate and anhydrous-β lactose which are elaborated in Table 1:

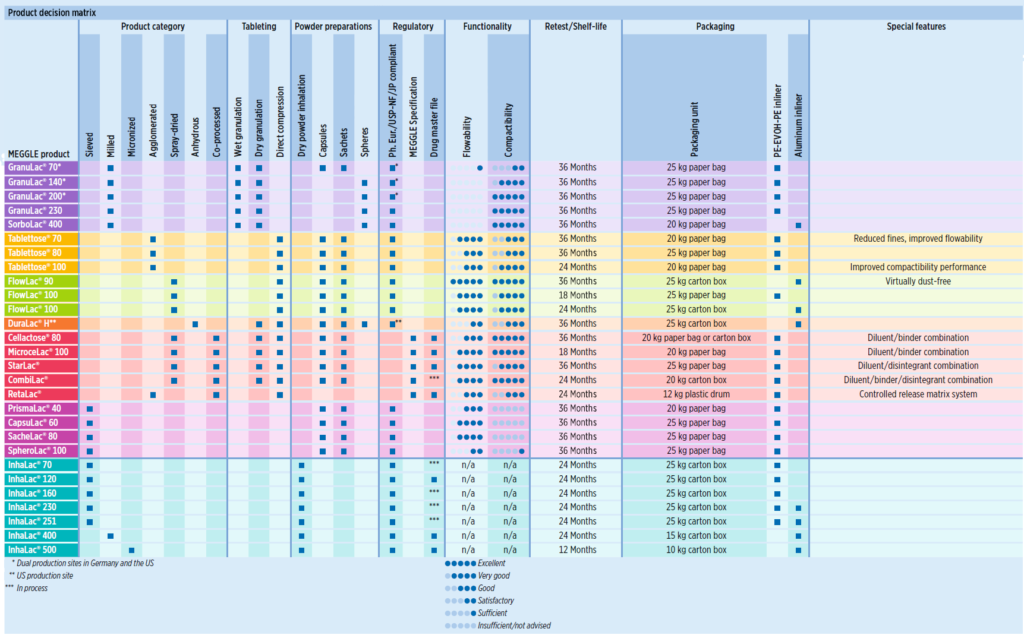

Meggle Wasserburg GmbH & Co. KG, headquartered in the Bavarian city of Wasserburg (Germany), has been servicing the pharmaceutical industry for the last 60 years with its broad lactose product portfolio. With intelligent innovations and exceptional product quality, MEGGLE took a leading role in the global business of pharmaceutical excipients. It is GMP and GDP certified according to EXCiPACT standard for the manufacturing, testing, storage and distribution of lactose and co-processed grades used as pharmaceutical excipient. Lactose grades offered by Meggle meet all the pharmacopoeial requirements of USP/NF, Ph. Eur. and JP monographs. It is GRAS listed and well supported by complete set of regulatory documentation.

Types of Lactose:

Meggle’s lactose range comprises of different product groups with more than 20 specialty grades, covering all areas from solid dosage forms, dry powder inhalations and parenteral dosage forms. These grades along with their applications are elaborated below in detail.

Sieved Lactose

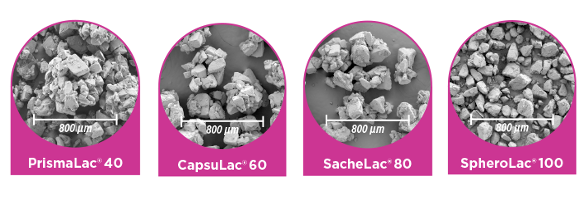

Alpha lactose monohydrate is derived from re-crystallization of lactose solution. This results in formation of tomahawk shaped crystals. Narrow fractionation of these randomly sized lactose crystals results in coarse sieved grades (Figure 2). Meggle’s sieved alpha-lactose monohydrate (listed below) are inherently free flowing in nature which is evident from their low Carr’s and flowability index. Hence these grades are recommended for capsule, sachet filling and powder triturates.

Grades: PrismaLac 40, CapsuLac 60, SacheLac 80, SpheroLac 100

Figure 2: SEM images of sieved lactose grades

Milled Lactose

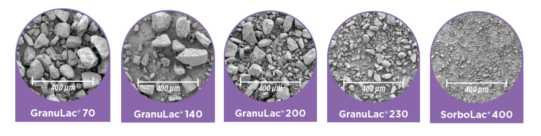

The tomahawk shaped crystals of lactose when milled, results in the formation of finer sharper-edged particles (Figure 3) called milled lactose. These grades (listed below) have poor flow but show good binding and compaction properties due to their small particle size and high specific surface area. Therefore they are are especially useful in wet and dry granulation and pelletization.

Grades: GranuLac 70, GranuLac 140, GranuLac 200, GranuLac 230, SorboLac 400

Figure 3: SEM images of milled lactose grades

Directly Compressible Lactose

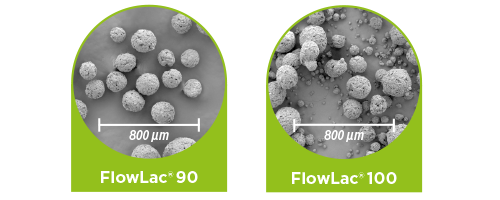

Spray Dried Lactose

When lactose is spray-dried, rapid water evaporation causes the formation of 10-15% amorphous lactose depending on the solids content and process conditions. Unlike alpha-lactose monohydrate which is known to exhibit brittle fracture during compaction, amorphous lactose deforms plastically. Due to the synergistic plastic and brittle nature of spray-dried lactose, it exhibits superior compactability. As can be seen in Figure 4, the spherical nature of Meggle’s FlowLac is attributed to spray-drying of fine milled alpha-lactose monohydrate suspension. This morphology along with the particle size distribution makes FlowLac the best flowable lactose amongst all the grades.

The amorphous lactose content in spray-dried grades ensures low friction with the die wall, preventing capping behavior as well. Spray-dried lactose also shows superior binding properties resulting in hard tablets.

Grades: FlowLac 100, FlowLac 90

Figure 4: SEM images of spray-dried lactose

FlowLac 100 is the standard grade of spray-dried lactose, providing excellent flowability and extraordinary compactability. FlowLac 90 is the superior grade developed by optimizing the amorphous lactose content to provide greater compactability compared to FlowLac 100. In addition, its particle size distribution makes FlowLac 90 virtually dust-free.

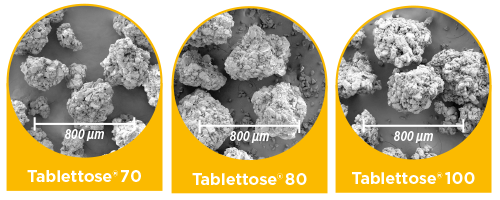

Agglomerated Lactose:

Agglomerated lactose is developed by combining the good flow of coarse lactose and good compactibility of fine powder grade. This grade is manufactured by wet granulation process by spraying water on fluidized fine particles of lactose monohydrate. This creates liquid bridges which bring the particles together. Upon drying, the excess water is evaporated and the bridges are maintained resulting in a very stable, non-hygroscopic alpha lactose monohydrate with no amorphous lactose. Meggle’s agglomerated lactose grades come under the name ‘Tablettose’.

Grades: Tablettose 70, Tablettose 80, Tablettose 100

As seen in Figure 5, Tablettose grades have a rough surface and a ‘blackberry’ or ‘popcorn’ like shape due to which they flow well. This morphology also provides stable, homogenous mixtures and is well suited especially for low dose actives.

Figure 5: SEM images of agglomerated lactose grades

Tablettose 80 is the standard grade in this series, which is suitable for direct compression. Tablettose 70 has a narrow particle size distribution, which reduces dust while Tablettose 100 is the finest of the three exhibiting superior compactibility. This could be attributed to the fact that it is prepared from smaller starting particle size lactose, which increases its binding capacity. Additionally, due to their morphology they are well suited for formulation of low dose actives.

Anhydrous Lactose:

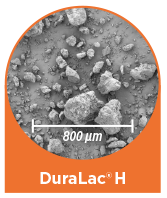

Roller / Drum drying of concentrated lactose solution above 93.5°C results in the formation of anhydrous lactose in the ratio of 80% beta and 20% alpha form. Anhydrous beta lactose is more brittle as compared to alpha lactose monohydrate and hence is well suited for direct compression and roller compaction. Moreover, exposure to such high temperature during manufacturing causes removal of crystal water resulting only in non-hygroscopic anhydrous form which is well suited for moisture sensitive actives.

On compaction, DuraLac H fragments and exposes clean surfaces with numerous binding sites. This gives rise to robust tablets in DC process as well as cohesive plugs in capsule manufacturing. DuraLac H is also recommended for dry granulation since it retains its compactibility after the initial slugging step.

Figure 6: SEM image of anhydrous lactose

Lactose Monohydrate Low Endotoxin:

Lactose is widely used in lyophilized injectable formulations as a stabilizer and to increase the solid content of the plug. It is also used in IV, IM, SC ready to use injections. Meggle offers Lactose Monohydrate, Low Endotoxin grade with a BET limit of NMT 5 EU/g.

Lactose Monohydrate for Inhalation:

Dry powder inhalers (DPI) are widely used in pulmonary drug delivery due to their ease of handling, portability, small size and no requirement of breath-actuation co-ordination. The carrier used in DPI formulations not only acts as a filler but also plays an important role in deposition of drug into the lungs. Lactose is one of the most widely used carriers in DPIs owing to the fact that it is inert, has a well-established safety profile and is accepted by regulatory and medical authorities. Meggle offers inhalation grade lactose under the brand name of InhaLac. These grades are manufactured by a two-step crystallization process to give preliminary lactose monohydrate with stringent microbial limits and endotoxin limit of less than 5 IU/g. The lactose is then either sieved, milled or micronized to give different InhaLac grades to cater to specific customer needs.

Sieved Grades: InhaLac 70, InhaLac 120, InhaLac 160, InhaLac 230, InhaLac 251

Milled Grades: InhaLac 400

Micronized Grade: InhaLac 500

Sieved, milled and micronized InhaLac grades show different morphology. Sieved ones contain partly tomahawk shaped crystals, which can occur as single or agglomerated particles. In contrast to sieved grades, milled and micronized grades consist of fine lactose particles. Their disrupted and sharp-edged appearance derives from a defined milling process.

Figure 7: SEM image of inhalation lactose grades

All InhaLac grades are BET tested and have stricter or even additional microbial limits compared to the current pharmacopoeia. This provides the highest security for use of InhaLac grades in DPI formulations.

Quick glance at MEGGLE´s lactose portfolio

Meggle offers a broad array of lactose grades with solutions for any formulation requirement. Table 2 outlines applications and properties, helping you decide the perfect grade of lactose for your formulation needs.

Table 2: Product Decision Matrix

Conclusion:

Lactose is a widely accepted filler of choice for varied applications from solid dosage forms to dry powder inhalations. Selecting the right grade of lactose should involve wise consideration of physicochemical properties like particle size distribution and surface morphology. It is known to be a versatile excipient due to its properties like compressibility, compactability, flowability, etc. and hence an in-depth understanding can certainly facilitate designing of formulation. Thus, lactose is and will continue to remain a popular choice in pharmaceutical industry.